Wedge Wire Filter Elements-High Pressure

Introduction

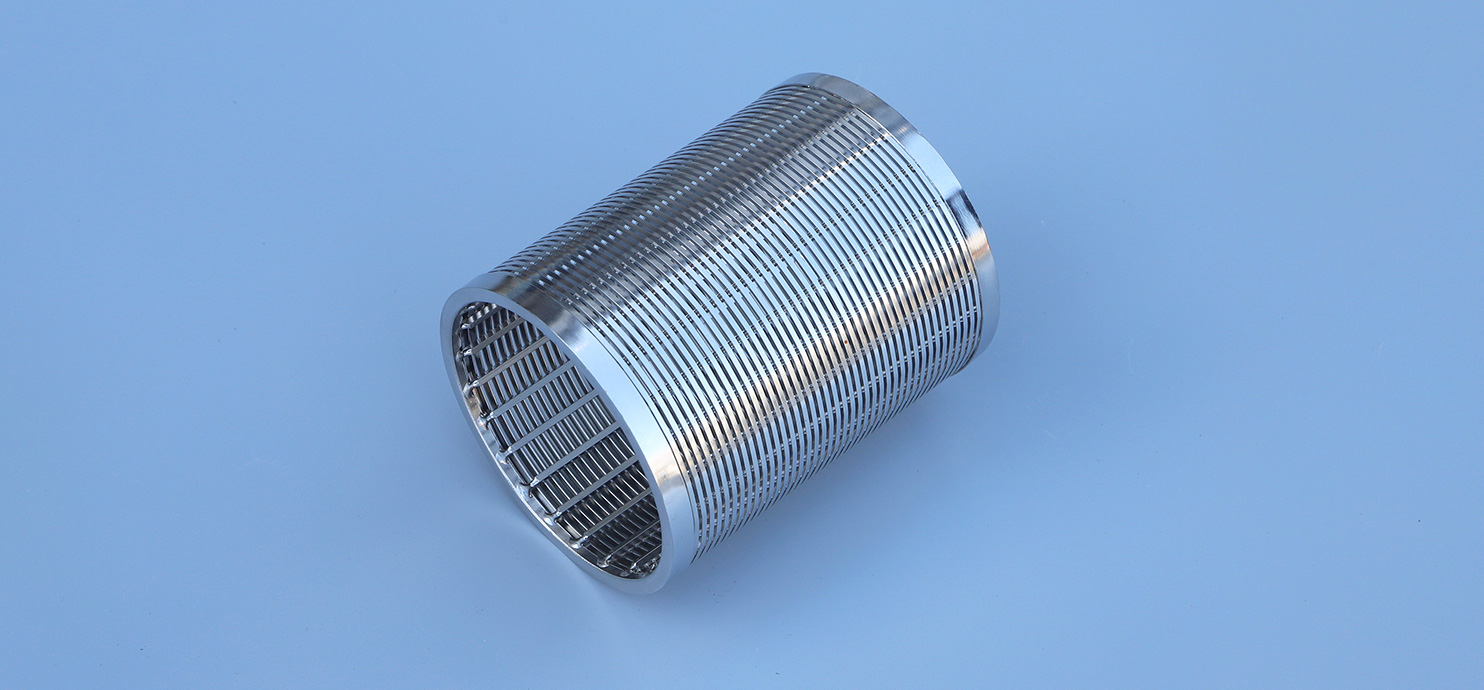

The wedge wire filter element is made of wedge wire mesh, and each contact point is welded to the rod with stainless steel wedge wire.It is designed to remove impurities and particles from liquids and gases, providing high quality filtration and separation.

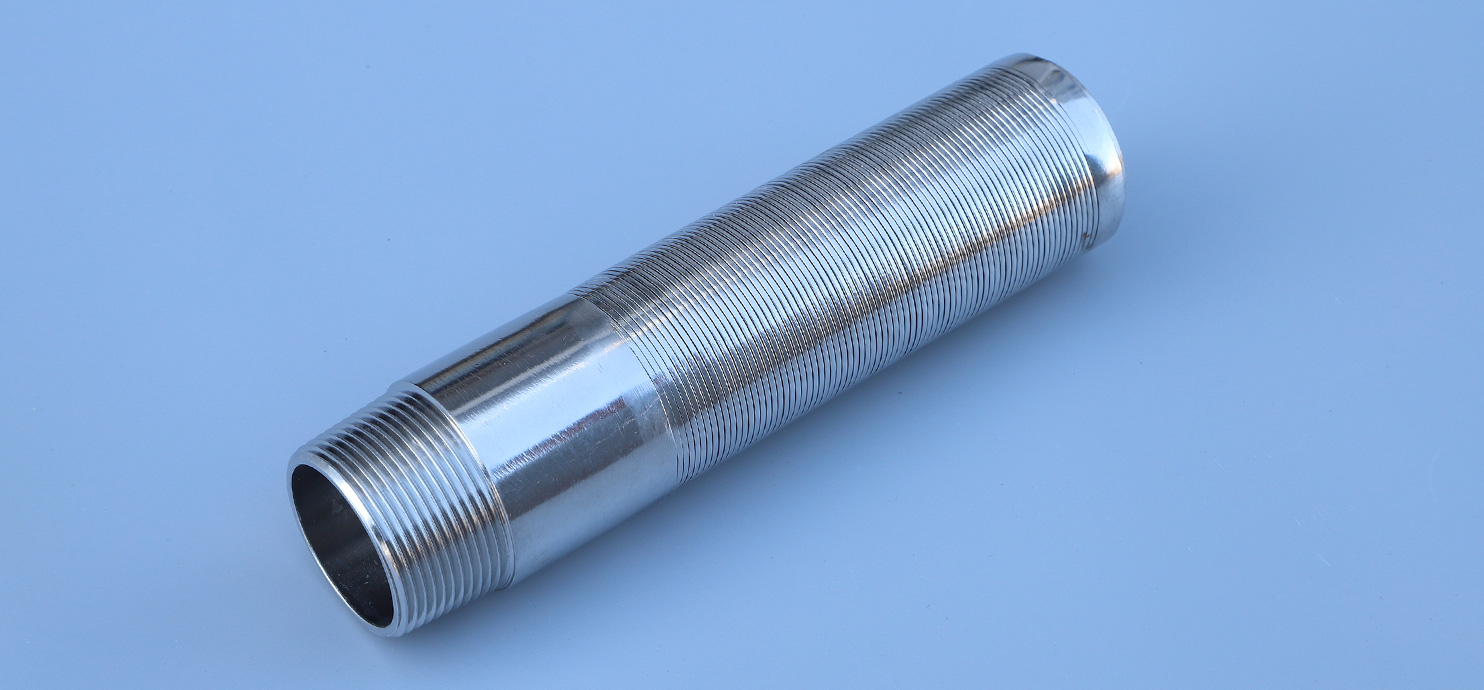

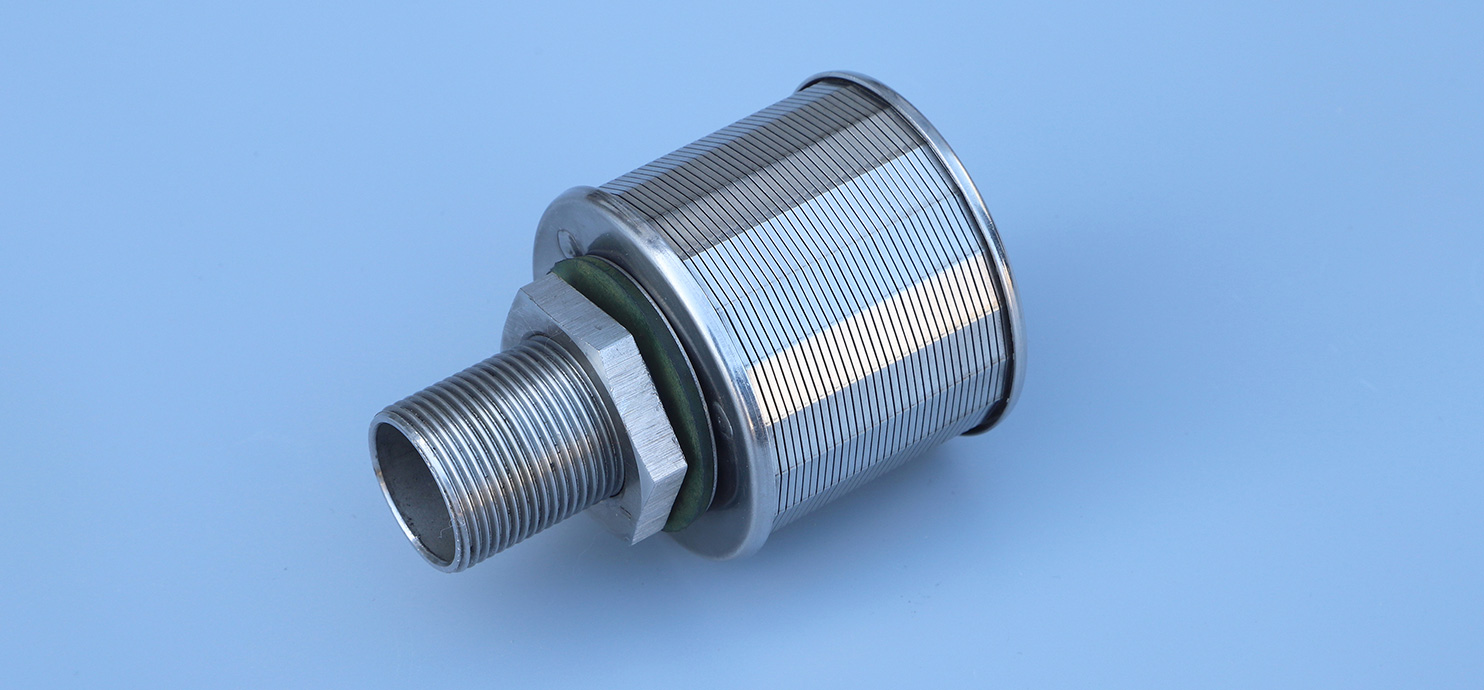

Display

Specification

The filter rating is from 15 to 800 microns.

The materials of main filter media are include 304、304L、316、316L、904L、Hastelloy etc

Characteristic

1) Precision V-type winding wire, with self-cleaning function, easy to clean and backwash, no blocking;

2) Smooth surface without edges and corners, Excellent roundness.

3) Diversified structure and filtration direction, Customized flexibly. From the inside out or from the outside in.

4) High strength, Good rigidity, Strong bearing capacity;

5) Uniform gap, Good permeability;

6) Wear resistance and corrosion resistance, Recyclable.

Application

The wedge wire filter element is widely used in various industries where efficient filtration and separation are required. Some of the common applications include:

Water Treatment

Wedge wire filter elements are commonly used in water treatment plants to remove impurities, sediment, and particles from water. They are used as pre-filters, primary filters, and final filters in different stages of the water treatment process.

Food and Beverage Industry

In the food and beverage industry, wedge wire filter elements are used to remove impurities and particles from liquids such as juice, wine, and beer. They are also used in the production of dairy products such as milk, cheese, and yogurt.

Petroleum and Chemical Industry

In the petroleum and chemical industry, wedge wire filter elements are used to filter various types of liquids and gases, such as crude oil, diesel fuel, and natural gas. They are also used in the production of chemicals and petrochemicals.

It provides high-quality filtration and separation, and is available in different sizes and configurations to meet specific application requirements.