Sintered Felt

Introduction

Sintered felt is composed of multiple layers of stainless steel fibers that have been sintered together to form a porous structure with a high filtration area and excellent permeability. This structure creates a tortuous path for the fluid to flow through, trapping impurities and particles in the felt while allowing the filtered fluid to pass through. The sintered felt has a high dirt-holding capacity, low pressure drop, and resistance to chemical corrosion, making it an ideal filter media for a wide range of applications.

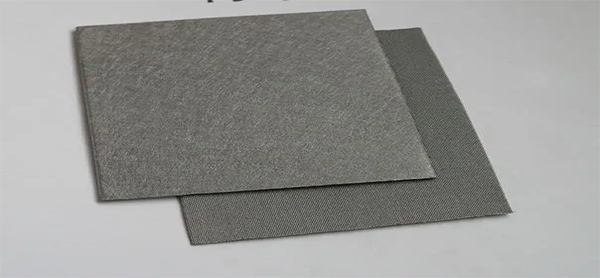

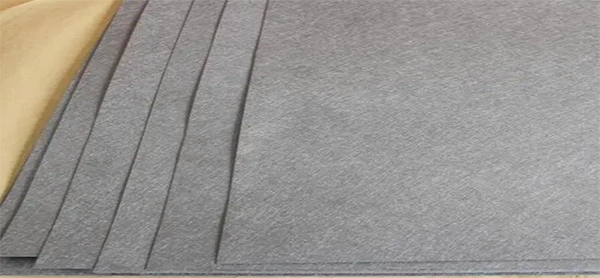

Display

Specification

Sintered felt is available in various grades, pore sizes, and thicknesses, depending on the filtration requirements of the application. The common specifications of sintered felt include:

- Materials: Stainless Steel 304, 316, 316L, etc.

- Grades: Coarse (3-40μm), medium (0.5-15μm), and fine (0.2-10μm)

- Filter Rating: 1-300μm

- Thickness: 0.3-3mm

- Maximum Operating Temperature: up to 600°C

- Sizes: customized according to customer requirements

Characteristic

1) High porosity and small filtration resistance

2) Large pollution carrying capacity and high filtration accuracy

3) Corrosion resistance and high temperature resistance

4) Easy to process, shape and weld;

Application

Sintered felt has a wide range of applications in industries such as chemical processing, oil and gas, pharmaceuticals, food and beverage, and water treatment. Some common applications include:

Gas Filtration

Sintered felt is widely used in gas filtration applications such as air intake filters for engines, dust collection systems, and venting applications where high filtration efficiency and high-temperature resistance are required.

Liquid Filtration

Sintered felt is an ideal filter media for liquid filtration applications such as filtration of chemicals, acids, solvents, and oils. It is commonly used in the pharmaceuticals, food and beverage, and water treatment industries where high-quality filtration is essential.

Catalytic Converter

Sintered felt is used in catalytic converters, which are devices that convert harmful emissions from vehicles into less harmful substances. The sintered felt layer is the substrate for the catalyst, allowing for maximum contact surface area between the gases and catalyst, resulting in efficient conversion.