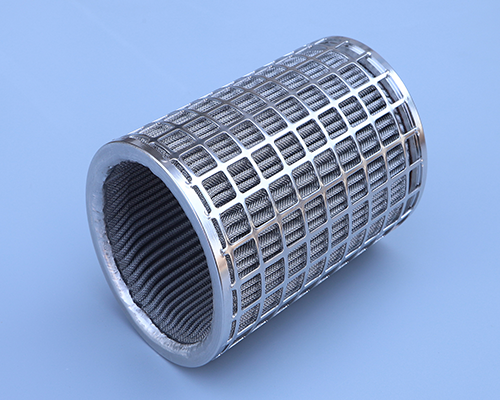

The dimensional accuracy of the stainless steel filter element is very important for its filtration effect, especially in the filtration series, customers often provide detailed drawing dimensions and give a certain error range for the outside diameter, the inside diameter and the height.However, why are these errors often difficult to accurately control in actual production?

First of all, the non-standard stainless steel filter element is often produced by custom, and the size of the material needs to be measured before production.In the process of unloading, manufacturers may ignore the accuracy of the sizing due to the pursuit of cost optimization, resulting in errors.In addition, the welding process may also be due to the negligence of production personnel or insufficient technology, resulting in unqualified dimensions.

Secondly, some manufacturers may omit mold costs in order to occupy a price advantage when quoting for customers.However, the mold is essential to ensure the size and quality of the product.There is no suitable mold for sizing, it is easy to produce dimensional errors in the production process, and even lead to defective products and waste products.This not only affects the willingness of customers to cooperate, but also may bring long-term economic losses to manufacturers.

Finally, in the welding process of stainless steel filter element, the degree of care of production personnel is also a key factor affecting the error.Even with the right size and mold, if the welding process is not properly operated, it may lead to unqualified size.Therefore, in the production process, manufacturers need to strengthen the training and management of production personnel to ensure the accuracy and stability of the welding process.

In short, the main reasons for stainless steel filter element error include inaccurate feeding size, lack of suitable mold and improper operation during welding.In order to improve product quality and customer satisfaction,AHT recommends that manufacturers strictly control these key factors during the production process to ensure the dimensional accuracy and stable quality of products.

AHT/ Hartong, Wire mesh Co., Ltd. as a manufacturer of wire mesh and filter products, can provide the required equipment and accessories, you can choose the right wire mesh and filter products according to your needs.

Post time: May-09-2024