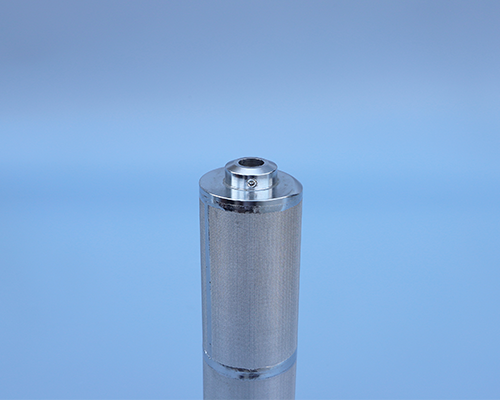

Because of its stable shape and excellent mechanical strength, sintered metal filters have become the filtration choice in various industrial fields, with outstanding filtration efficiency and the ability to withstand extreme environments. In this regard, how to choose a suitable supplier of sintered metal filters becomes a prerequisite for having high-quality sintered metal filters.

Material quality

High quality sintered metal filter for the choice of raw materials should be strictly controlled, reputable sintered metal filter suppliers usually use high-grade metal as raw materials, such as stainless steel, nickel or titanium. These metal raw materials can not only improve the filtration performance of metal filters, but also ensure their harsh environmental resistance and service life.

Manufacturing process

The manufacturing process of the sintered metal filter supplier is critical. Under normal circumstances, a reliable supplier will have a professional R & D team, advanced sintering technology, high-quality equipment support, rigorous quality control to ensure that the metal filter maintains the best performance and meets industry standards.

Custom features for compliance

Different applications require different specifications, and a leading supplier of sintered metal filters inevitably offers customization options that allow customers to provide aperture, size specifications, and compliance with lS0 standards. This flexibility ensures that metal filters can meet the unique needs of a variety of applications.

In short, when looking for sintered metal filter suppliers, the above points are essential, these conditions will help ensure that you have a metal filter that meets your needs, AHT/ Hartong wire mesh Co., Ltd. as a manufacturer of metal filter products, can provide the required equipment and accessories, you can choose the right wire mesh and filter products according to your needs.

Post time: Oct-31-2024