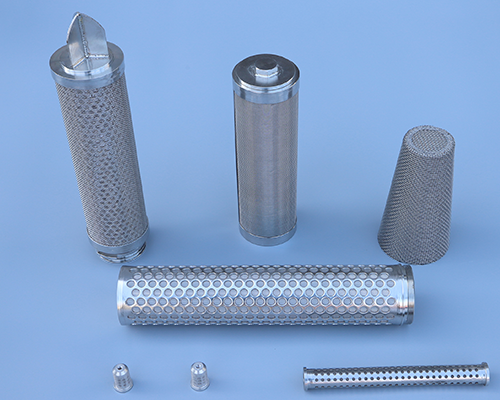

Metal filter elements are the ideal accessories for efficient filtration of liquid and gas systems in the current industrial environment, its durability, reliability and cost performance have become the main concerns of customers to buy, in order to dispel customer concerns, we take a look at the processing process of metal filter elements.

The selection of metal materials is a prerequisite for the processing of high-quality metal filter elements. Common metal raw materials are stainless steel, aluminum and other metal alloys (professional producers of metal filter elements will examine the corrosion resistance, strength and thermal stability of metal alloys). Once the metal material is identified, it is then subjected to processes including annealing and surface treatment to enhance its ductility and resistance to wear.

The next is the structural processing of metal filter elements, due to the complexity of its design, it will involve welding, stamping, machining and other technologies. In this process, we should pay great attention to the size and surface characteristics, because it will directly affect the filtration accuracy of the metal filter element, and usually use advanced technologies such as laser cutting and CNC machining to achieve its high precision.

When the metal filter element is formed, it goes through a thorough cleaning process to ensure that it is free of any contaminants, achieving optimal filter performance without compromising the quality of the filtered fluid.

The final step in the processing of metal filter elements is quality control. Each metal filter element is subjected to rigorous testing to assess its filtration performance, pressure resistance, durability and overall integrity to meet the demanding requirements of a variety of industries, ensuring that the highest quality metal filter elements reach the market.

In conclusion, the processing of metal filter elements is a precision process integrating material selection, molding, cleaning and quality inspection. AHT/ Hartong Wire Mesh Co., Ltd. as a metal filter manufacturer, can provide the necessary equipment and accessories to ensure the excellent performance and reliability of the metal filter elements, you can choose the right metal filter cartridges according to your needs.

Post time: Dec-19-2024