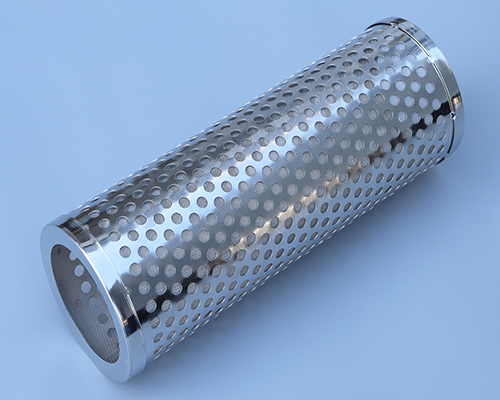

Long known for their durability, corrosion resistance and high temperature resistance, stainless steel filter tubes are widely used in industries where high-quality filtration solutions are in demand and are ideal for industrial applications such as water treatment and food processing. Therefore, in order to meet the specific needs of all walks of life, we have launched a special stainless steel filter tube customization service, today we will introduce its customization process.

Firstly, we will conduct a comprehensive assessment of the requirements of the stainless steel filter application, such as the type of fluid being filtered, the flow rate and the particle size, which are important indicators to determine the specifications of the stainless steel filter. Above we will work closely with you to understand your exact needs and ensure that the final product fits your application exactly.

Once your application needs have been determined, the next step is to determine the appropriate grade of stainless steel. Because different grades of stainless steel provide different levels of corrosion resistance and strength, and significantly affect the performance of stainless steel filter tubes. Usually 316 stainless steel is preferred because of its excellent resistance to chloride, suitable for Marine applications.

After the raw material is selected, the diameter, length and wall thickness of the stainless steel filter tube are determined to optimize the filtration efficiency. In addition, the customization service focuses on capturing a specific particle size and allowing the required flow through, and the mesh size of the stainless steel filter tube must be precise.

Finally, the stainless steel filter tube processing process combines cutting, welding, machining and surface treatment and other advanced technologies, the entire process implements strict quality control to ensure the production of high-quality stainless steel filter tubes, and in line with industry standards to meet customer needs.

In conclusion, the customization process of stainless steel filters is the key to achieving their optimal filtration performance. As a specialized metal filters manufacturer, we start by understanding the specific needs of your application to ensure that you receive a tailored solution to improve the efficiency of their operations.

Post time: Jan-07-2025