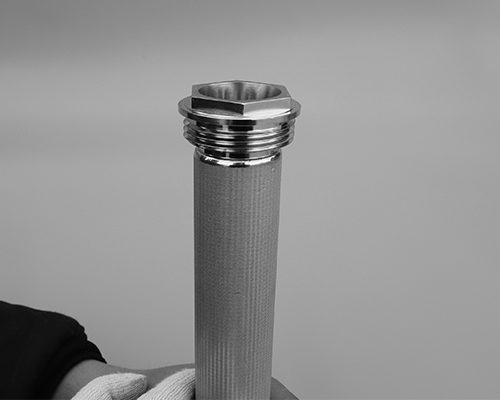

Sintered wire mesh filter is made of multi-layer woven wire mesh as raw materials, fused together through sintering calendering and other processes to form a robust and durable metal filter medium. A series of prerequisites determine that the sintered wire mesh filter is suitable for a variety of harsh filtration environments, and has become the first choice for filtration needs in various industrial fields. Today we will reveal its advantages in industrial filtration systems.

Sintered wire mesh filters offer superior strength and durability. Traditional filters often degrade or clog due to prolonged use, while sintered wire mesh filters can not only withstand high pressure and temperature, ensure a longer service life in harsh environments, but also reduce the frequency of replacement, and ultimately reduce operating costs.

Sintered wire mesh filters are known for their excellent filtration efficiency. They are designed to reach specific pore sizes, allowing precise filtration of particles from coarse to fine, meeting the unique needs of different filtration systems for chemical processing, food and beverage, and wastewater treatment industries.

Sintered wire mesh filters are designed to be easy to clean and maintain. The rugged construction allows for rinsing and other cleaning methods without damaging the filter, ensuring consistency in filtration accuracy. This ease-of-maintenance feature helps reduce downtime and increase the efficiency of industrial operations.

In conclusion, sintered wire mesh filters have become an excellent choice for a wide range of applications because of their unique advantages.

AHT/ Hartong Wire Mesh Co., Ltd. as a metal filtration manufacturer, can provide the necessary equipment and accessories to meet the needs of different industries facing reliable and efficient filtration solutions, you can choose the right metal filter elements according to your needs.

Post time: Dec-17-2024