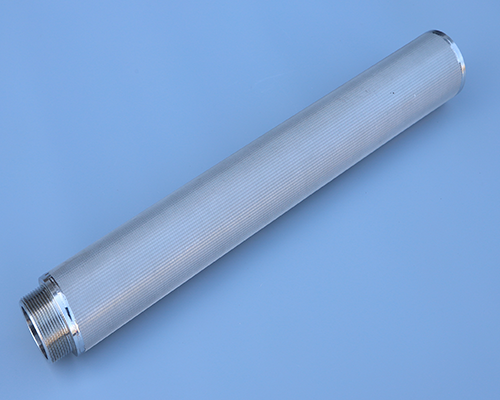

With the continuous maturity of industrial technology, sintered stainless steel filter cartridge has become an important part of the chemical industry, providing unparalleled filtration solutions for industrial filtration, improving work efficiency and product quality. These filters are manufactured through a sintering process, which involves melting metal particles at high temperatures and then sintering, pressing, and calendering porous products under vacuum.This unique design has excellent filtration capabilities.making it ideal for a variety of applications in the chemical industry.

One of the main applications of sintered ss filter cartridges in the chemical industry is to filter corrosive chemicals. The robustness of stainless steel ensures that these cartridges can withstand harsh environments, including high temperatures and corrosive chemicals. The durability of stainless steel not only extends the service life of the filter, but also reduces the frequency of replacement in industrial applications, which also greatly saves a lot of costs for sintered ss filter cartridge manufacturers

In addition to its durability, sintered Ss filter cartridges provide excellent particle retention. The fine pore structure effectively traps pollutants, including particles, sediments, and even microorganisms. Because the purity of the raw material and the final product is most important, this advantage of sintered Ss filter cartridge is particularly important in the chemical industry. After treatment to ensure a clean, non-polluting material, sintered ss filter cartridge precisely helps maintain product integrity and compliance with industry standards.

Moreover, the sintered ss filter cartridge is easy to clean and maintain. Unlike conventional filter media, which require frequent replacement, sintered ss filter cartridges can often be back washed or chemically cleaned, making them a filtration product for more sustainable applications. In the continuous production process, the downtime spent on maintenance can be extremely expensive, and this function is particularly important in the continuous production process.

In short, the ability of sintered stainless steel filter cartridges to withstand harsh conditions, combined with excellent particle retention and ease of maintenance, makes them an indispensable asset in the production and processing of manufacturers who optimize operations and ensure product quality.AHT/ Hartong, Wire mesh Co., Ltd. as a metal filter manufacturer, can provide the required equipment and accessories, you can choose the right metal filter elements according to your needs.

Post time: Sep-30-2024