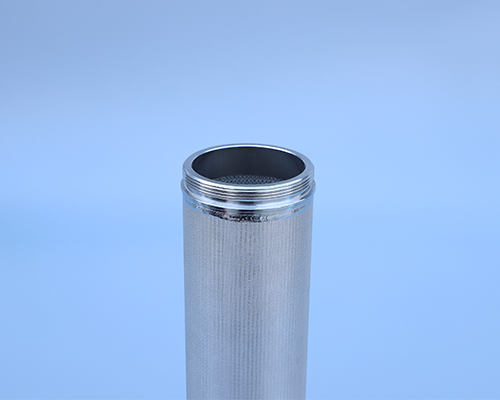

Sintered metal filters take metal powder as raw material, through high temperature vacuum sintering.pressing, calendering to form a solid structure, resulting in highly porous materials, which can efficiently separate solids from liquids and gases. Because of its unique production and processing methods and obvious advantages, it has become the first choice for filtration and screening in various industrial fields.

High filtration accuracy

Sintered metal filters have high porosity and a stable internal structure that allows for efficient fluid flow while effectively capturing fine particles.

Durability

Metal sintered filter element is made of strong metal powder as raw material, through vacuum sintering calendering and other processes, has excellent impact resistance to harsh environments, compared with traditional filters, to ensure the stability and service life in high pressure, high corrosion environment, reduce the frequency of replacement.

Environmentally friendly and easy to clean

Traditional metal filters are easy to clog, not easy to clean, sintered metal filters can be repeatedly cleaned and used, simple maintenance, cost-effective, and reduce waste, making them a more sustainable choice than disposable metal filters.

Versatility

Because of its unique production process, adaptability to different environments and materials,and high density filtration rate, sintered metal filters can be used in a variety of industrial industries,including pharmaceutical manufacturing, food and beverage and petrochemical,etc.

In short, AHT/ Hartong wire mesh Co.. Ltd. as a metal filter manufacturer, can provide the required equipment and accessories, the production of sintered metal filter has the advantages of high quality, high efficiency making it an excellent choice for modern filtration needs, to ensure the best performance in a variety of applications,you can choose the right wire mesh and filter products according to your needs.

Post time: Oct-29-2024