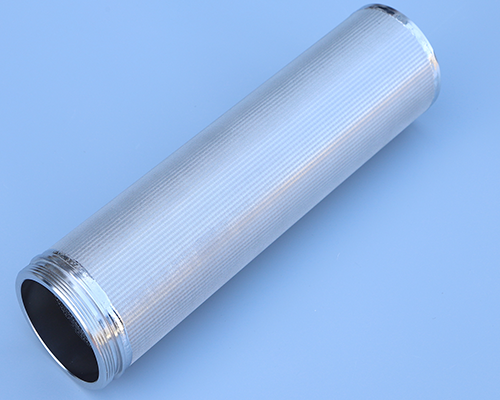

Sintered filters are an essential component in many industrial and manufacturing processes, providing a reliable means of separating solids from liquids or gases. When it comes to selecting a sintered filter, it’s crucial to understand how to judge the quality of the filter to ensure optimal performance and longevity.

One of the key factors to consider when evaluating the quality of a Sintered Filter is the material used in its construction. High-quality sintered filters are typically made from durable materials such as stainless steel, bronze, or nickel, which offer excellent corrosion resistance and mechanical strength. These materials are capable of withstanding harsh operating conditions and are less prone to degradation over time, ensuring a longer service life for the filter.

Another important aspect to consider is the pore size and distribution of the sintered filter. A high-quality filter will have a uniform and consistent pore structure, which is essential for achieving precise filtration and preventing the passage of unwanted particles. The pore size should be carefully matched to the specific application requirements, ensuring efficient filtration without excessive pressure drop or flow restriction.

In addition to the material and pore structure, the manufacturing process used to produce the sintered filter also plays a crucial role in determining its quality. Filters that are produced using advanced sintering techniques, such as powder metallurgy, are more likely to exhibit superior mechanical properties and dimensional accuracy. This results in a filter that is more reliable and less prone to failure under demanding operating conditions.

Furthermore, the design and construction of the sintered filter should be carefully evaluated. High-quality filters are typically engineered with precision, featuring robust construction and seamless integration of components. This ensures that the filter can withstand high pressures and temperature variations without compromising its performance.

When assessing the quality of a sintered filter, it’s also important to consider the manufacturer’s reputation and adherence to industry standards. Reputable manufacturers who comply with stringent quality control measures and certifications are more likely to produce filters that meet or exceed performance expectations.

In conclusion, when evaluating the quality of a sintered filter, it’s essential to consider the material, pore structure, manufacturing process, design, and the manufacturer’s reputation. By paying attention to these key factors, it becomes possible to select a high-quality sintered filter that delivers reliable and efficient filtration for a wide range of industrial applications.

AHT/ Hartong, Wire mesh Co., Ltd. as a manufacturer of wire mesh and filter products, can provide the required equipment and accessories, you can choose the right wire mesh and filter products according to your needs.

Post time: Jun-04-2024