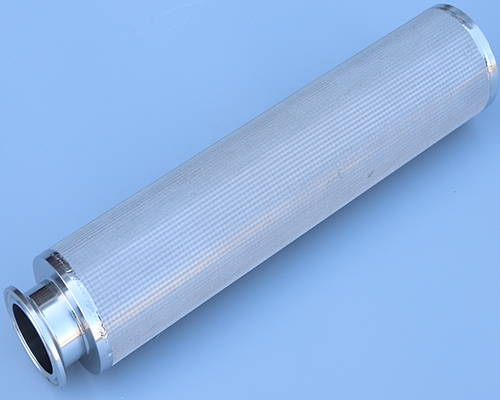

When it comes to selecting a quality sintered filter cartridge, there are several key factors to consider in order to ensure optimal performance and longevity. Sintered filter cartridges are widely used in various industries for their ability to effectively remove impurities and contaminants from liquids and gases. Here are some important considerations to keep in mind when choosing a sintered filter cartridge:

Material Quality: One of the most crucial factors in selecting a quality sintered filter cartridge is the material used in its construction. High-quality sintered filter cartridges are typically made from durable materials such as stainless steel, bronze, or nickel, which offer excellent corrosion resistance and mechanical strength. It is important to ensure that the material used is compatible with the specific application and the substances being filtered.

Filtration Efficiency: The filtration efficiency of a sintered filter cartridge is another important aspect to consider. Look for cartridges that offer a high level of filtration efficiency, capable of effectively removing particles of various sizes from the fluid or gas being filtered. This will help ensure that the end product meets the required purity standards.

Flow Rate: The flow rate of the sintered filter cartridge is another critical factor to consider. It is important to select a cartridge that can accommodate the required flow rate without compromising the filtration efficiency. A quality sintered filter cartridge will be designed to maintain a consistent flow rate while effectively capturing contaminants.

Pressure and Temperature Resistance: Depending on the specific application, the sintered filter cartridge may be subjected to high pressures and temperatures. It is essential to choose a cartridge that can withstand these conditions without experiencing degradation or failure. High-quality sintered filter cartridges are designed to operate effectively under challenging pressure and temperature conditions.

Manufacturer Reputation: When selecting a sintered filter cartridge, it is important to consider the reputation of the manufacturer. Look for a reputable manufacturer with a proven track record of producing high-quality filtration products. A reliable manufacturer will adhere to strict quality control standards and provide technical support and expertise.

In conclusion, selecting a quality sintered filter cartridge involves considering factors such as material quality, filtration efficiency, flow rate, pressure and temperature resistance, and the reputation of the manufacturer. By carefully evaluating these factors, you can ensure that the sintered filter cartridge meets the specific requirements of your application and delivers reliable, long-lasting performance.

AHT/ Hartong, Wire mesh Co., Ltd. as a manufacturer of wire mesh and filter products, can provide the required equipment and accessories, you can choose the right wire mesh and filter products according to your needs.

Post time: Aug-02-2024