Rimed filter discs are essential components in various industrial and commercial applications, serving as a crucial element in filtration systems. When choosing the right rimed filter discs for your specific needs, it’s important to consider their features and characteristics to ensure optimal performance and efficiency.

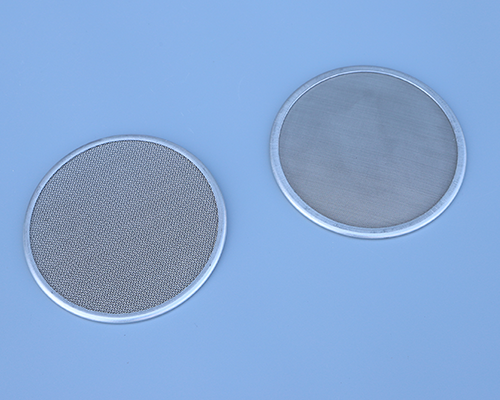

One of the key features to consider when selecting rimed filter discs is the material. These discs are commonly available in materials such as stainless steel, brass, and plastic. Stainless steel discs are known for their durability and resistance to corrosion, making them suitable for demanding environments. Brass discs offer excellent conductivity and are often used in applications where electrical conductivity is essential. Plastic discs, on the other hand, are lightweight and cost-effective, making them ideal for less demanding filtration tasks.

Another important feature to consider is the pore size of the filter discs. The pore size determines the level of filtration and the size of particles that can be effectively removed. It’s crucial to choose a pore size that is suitable for the specific contaminants or particles that need to be filtered out. For example, if the application involves filtering fine particles, a filter disc with a smaller pore size would be more appropriate.

Additionally, the shape and dimensions of the rimed filter discs should be taken into account. Different applications may require specific shapes or sizes to fit into existing filtration systems or equipment. It’s important to ensure that the dimensions of the filter discs align with the requirements of the application to achieve seamless integration and optimal performance.

When selecting rimed filter discs, it’s also essential to consider the operating conditions and environmental factors. Factors such as temperature, pressure, and chemical exposure can impact the performance and longevity of the filter discs. Choosing discs that are designed to withstand the specific operating conditions will ensure reliable and consistent filtration performance.

In conclusion, the features of rimed filter discs play a crucial role in their selection for various filtration applications. By considering the material, pore size, dimensions, and operating conditions, you can choose the most suitable filter discs to meet your specific filtration needs. It’s important to assess these features carefully to ensure efficient and effective filtration in your industrial or commercial processes.

AHT/ Hartong, Wire mesh Co., Ltd. as a manufacturer of wire mesh and filter products, can provide the required equipment and accessories, you can choose the right wire mesh and filter products according to your needs.

Post time: Jun-28-2024