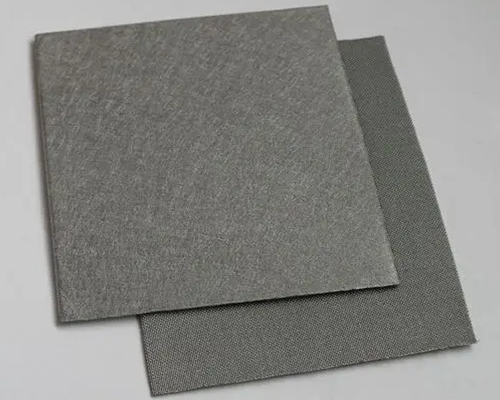

Stainless steel sintered felt as a high precision and long life filter medium although its production cost is relatively high, but its application value in the field of filtration can not be ignored.In order to reduce production costs and meet environmental requirements, we can take advantage of its reproducible characteristics and recyle it.In the regeneration process, we need to consider the working state of the filter element, the type of pollutants handled in the filtration system and the setting of the cleaning procedure.

The following are several general cleaning principles and methods :

1.Chemical cleaning method

The method mainly relies on chemical solvents such as acid-base cleaning solution, which is the most effective method for treating polyester condensate filters.By selecting the appropriate chemical solvent, the dirt and impurities on the filter can be effectively removed.

2.Ultrasonic cleaning method

Ultrasonic cleaning uses the wave energy of continuous pressure and expansion to create gas hols in the liquid and break continuous,so as to achieve efficient cleaning effect.This method is particularly effective for removing stubborn dirt on the surface of the filter element.

3.Heat treatment cleaning method

Heat treatment cleaning method When the chemical cleaning method can not achieve the desired effect, we can consider the use of heat treatment cleaning method.Vacuum pyrolysis,heating ovens,liquefaction beds and hot salt baths are all commonly used heat treatment cleaning technologies.After cleaning,it is necessary to check the bubbling integrity of the filter element and determine its pressure drop to ensure that the cleaning effect meets the requirements of use.

By using these cleaning methods, we can achieve the regeneration of stainless steel sintered felt filter media, not only reducing production costs, but also help to protect the environment.At the same time, these cleaning methods also help to improve the filtration efficiency and service life of the filter element, and contribute to the sustainable development of the enterprise.

AHT/ Hartong, Wire mesh Co., Ltd. as a manufacturer of wire mesh and filter products, can provide the required equipment and accessories, you can choose the right wire mesh and filter products according to your needs.

Post time: May-10-2024