Multi-Layer Sintered Mesh for Filter

Introduction

The widely used and standard combination is 5-layer sintered wire mesh. It is combined by Five different layers or multi-layer of stainless steel wire mesh, and then sintered together through being vacuum sintered, compressed, and calendared, forming a porous product.

Sintered wire mesh is made form multiple layers of woven wire mesh panels using a sintering process. This process combines heat and pressure to permanently bond multi-layers of mesh together. The same physical process used to fuse individual wires together within a layer of wire mesh is also used to fuse adjacent layers of mesh together. This creates a unique material offering excellent mechanical properties. It is ideal material for purification and filtration.

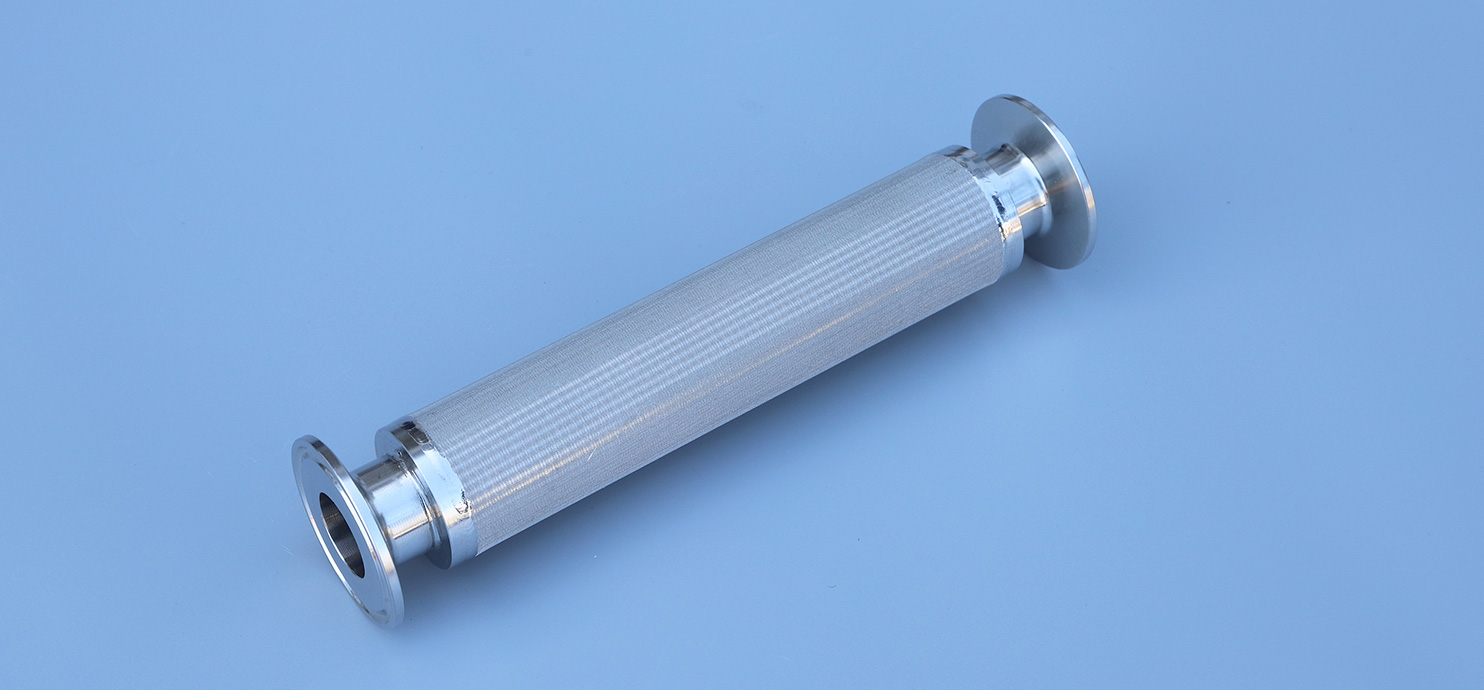

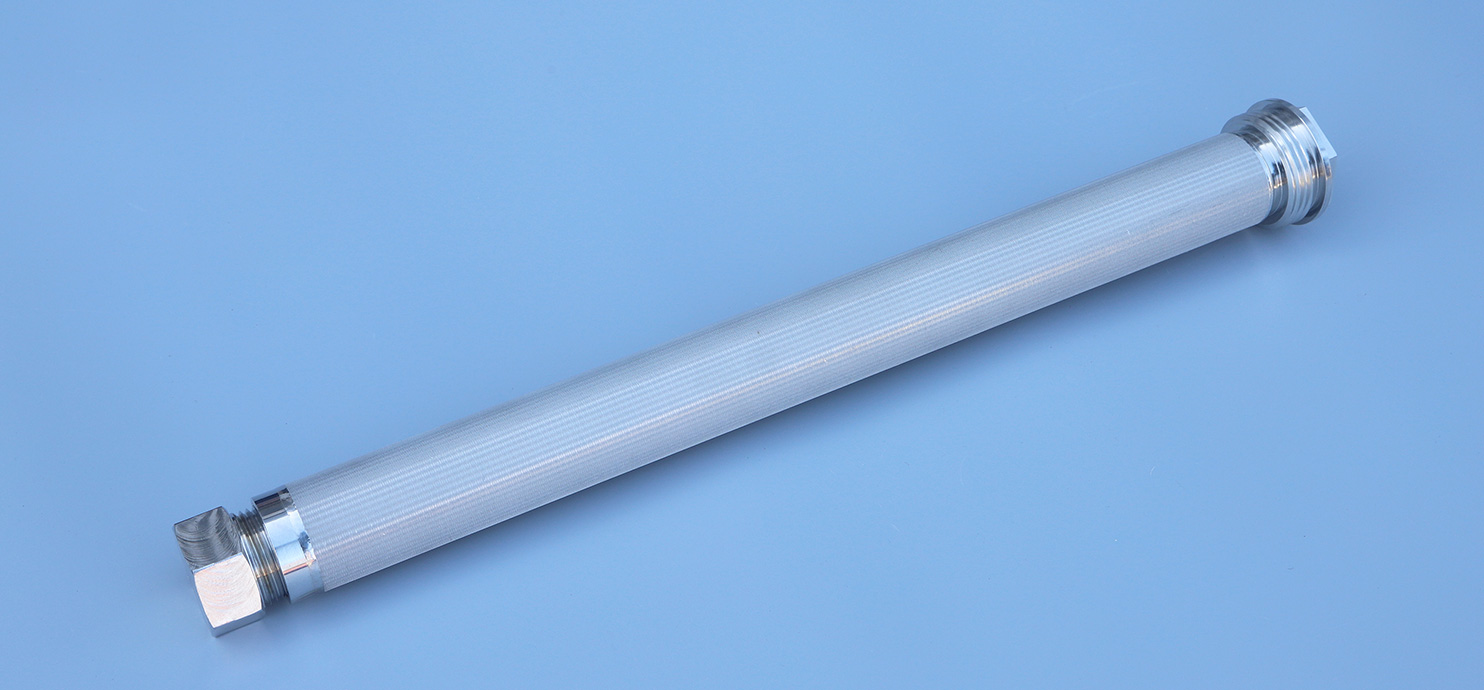

Display

Specification

1.Filtration rate: 1-200μm;

2.Temperature: -50℃-800℃

3. Diameter: 14-800mm, Length: 10-1200mm

4. Connector Type

Sintered porous filter can work with a variety of connectors and can be customized upon request.

●Standard connector (215, 222, 226)

●Thread connection (M20, M30, M32, M42, etc.)

●Flat/DOE

●Special customized connector

5.Allow customization

Characteristic

1)High strength, Good rigidity, No materials shedding;

2)Uniform pores, Good permeability;

3)High filtering accuracy, Excellent filtering performance;

4)High temperature resistance, Corrosion resistance;

5)Easy to clean, especially suitable for reverse cleaning, Recyclable.

Application

Sinter wire mesh filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particle, transpiration cooling under extremity high temperature, control air flow distribution, enhancement of heat and mass transfer, noise reduction, current limitation, and wildly used in aerospace, petrochemical industry, pharmaceutical industry, environmental protection industry.

1 Polyester

2) Petrochemical, petroleum refining

3)Chemicals and pharmaceutics

4)Food refining or cycling

5)Filtration of pure water and gas