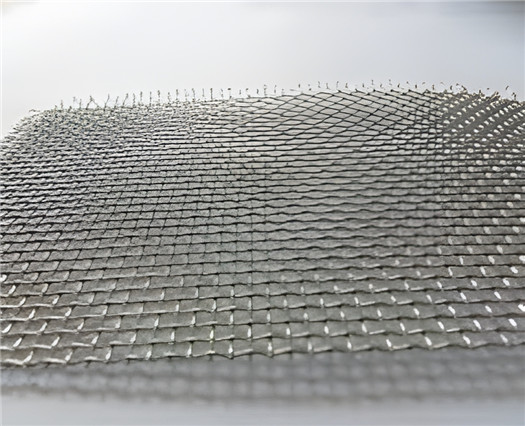

Monel Wire Mesh

Introduction

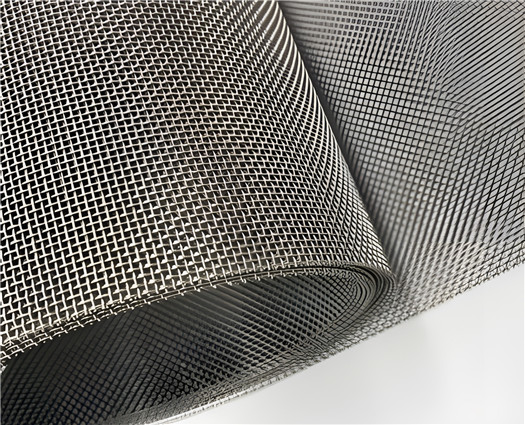

Monel wire mesh is known for its excellent strength, corrosion resistance, and heat resistance. It is commonly used in applications where durability and resistance to harsh environments are required.

Monel wire mesh is often used in industries such as chemical processing, marine, aerospace, and oil and gas. It is suitable for applications such as filtration, separation, sieving, and reinforcement.

Display

Specification

Grade: Monel 400

Melting Point: 1300 degree-1350 degree

Mesh Counts: from 1-200 mesh/inch

Micron Size:10-1000 microns

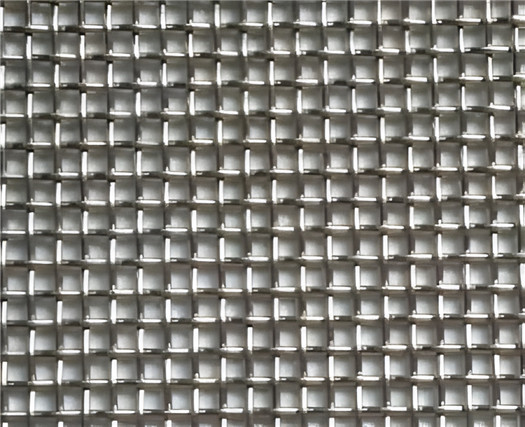

Wire Diameter: 0.025-2.03 mm

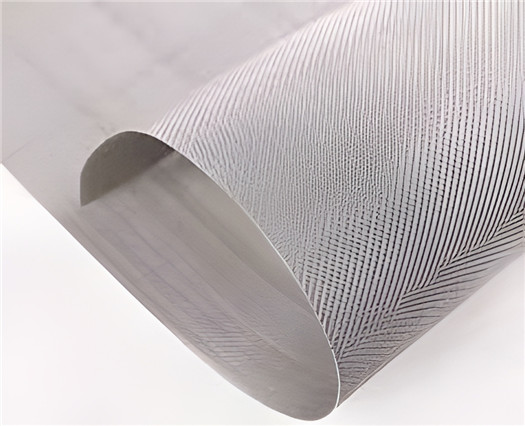

Weaving: Plain weave, twill weave, dutch weave.

Mesh Surface: Flat and smooth

Hole Shape: Square

Characteristic

● Resistance to static and running seawater attack

● High mechanical strength

● Resistance to SCC

● Prevents attack by acidic and alkali media

● Perfect finish

● Prolong service

Application

Chemical Processing: Monel wire mesh is highly resistant to corrosion and chemical attack, making it suitable for use in the chemical processing industry. It is used for filtration, separation, and as a catalyst support in processes involving corrosive chemicals.

Oil and Gas Industry: Monel wire mesh is utilized in the oil and gas industry for applications such as filtration, erosion control, and protection against sand and other particulates in drilling and production equipment.

Electrical and Electronics: Monel wire mesh can be used in electrical and electronic applications where conductivity, durability, and resistance to corrosion are required. Examples include shielding, grounding, and antenna applications.