Cylinder Filter

Metal Cylinder Filter Introduction

The metal cylinder filter, also known as the metal filter tube, cylindrical mesh filter and metal mesh tube, is usually made of high-quality stainless steel as raw materials, and composed of woven wire mesh, punched plate, welded mesh, etc., through a cylindrical perforated support structure. As a professional stainless steel cylinder filter manufacturer, AHT/Hartong Wire Mesh Co., Ltd. adopts stainless steel wire mesh as the filter medium, which is installed on the perforated support structure to ensure the adhesion of the filter material and the mesh at the same time, to achieve the effect of efficient filtration. It's widely used in petroleum, plastics, electroplating, chemical industry, ceramics, sugar and other industries. We can customize to the dimensions or drawings required by our customers. If you are interested in further discussing the technical details of the cylindrical mesh filter or cooperation opportunities, please feel free to contact us.

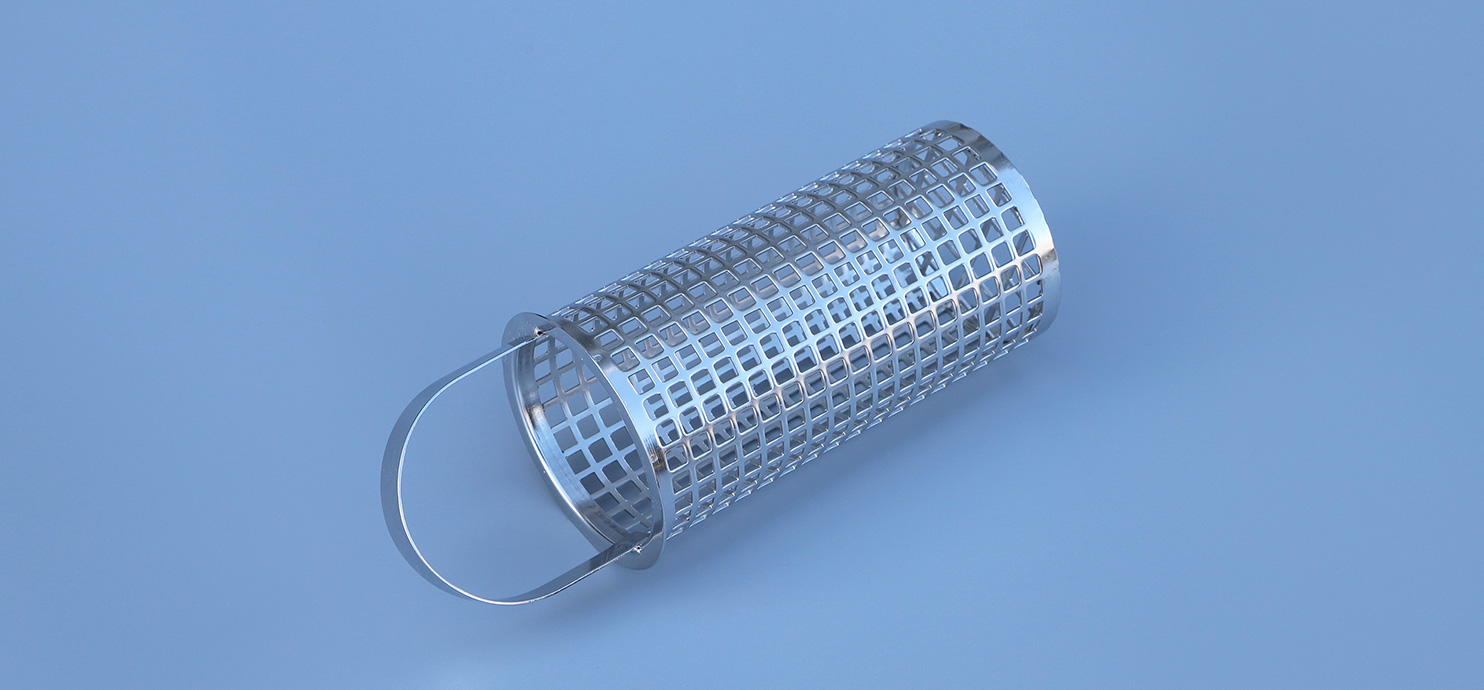

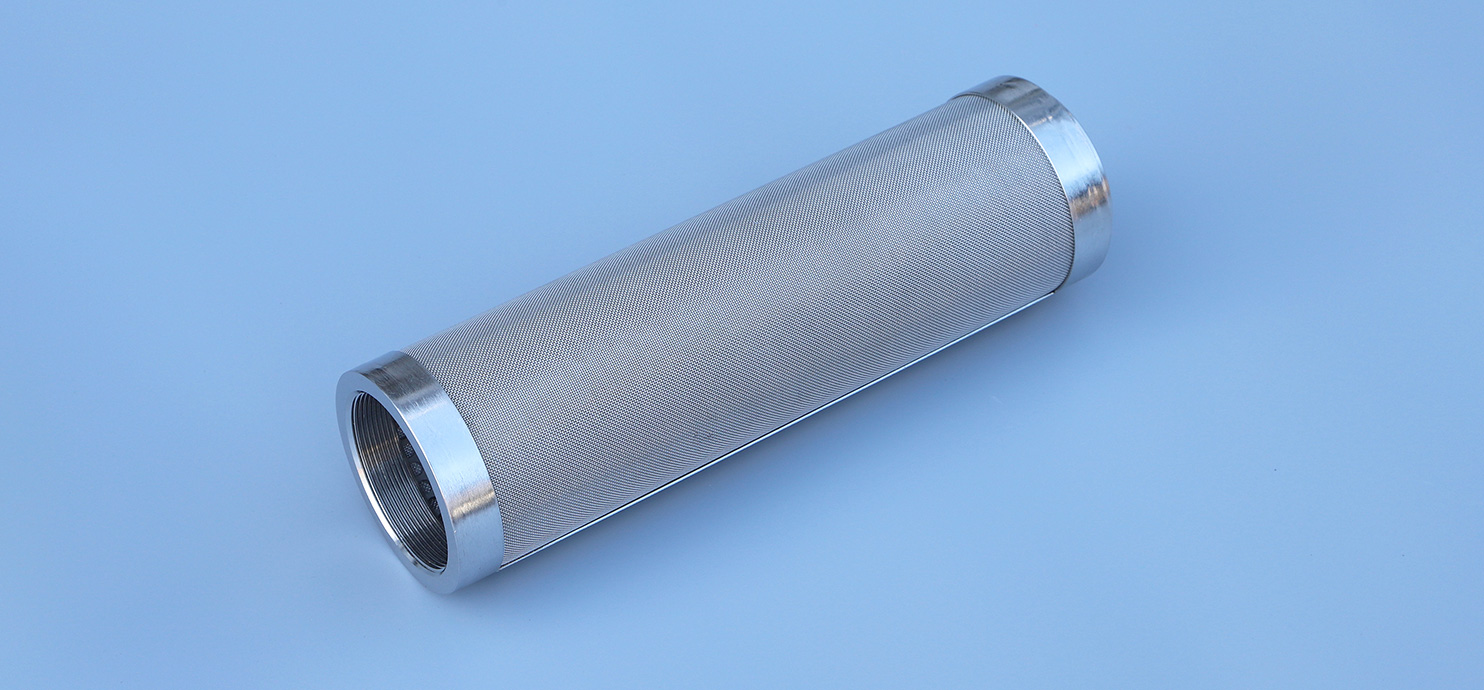

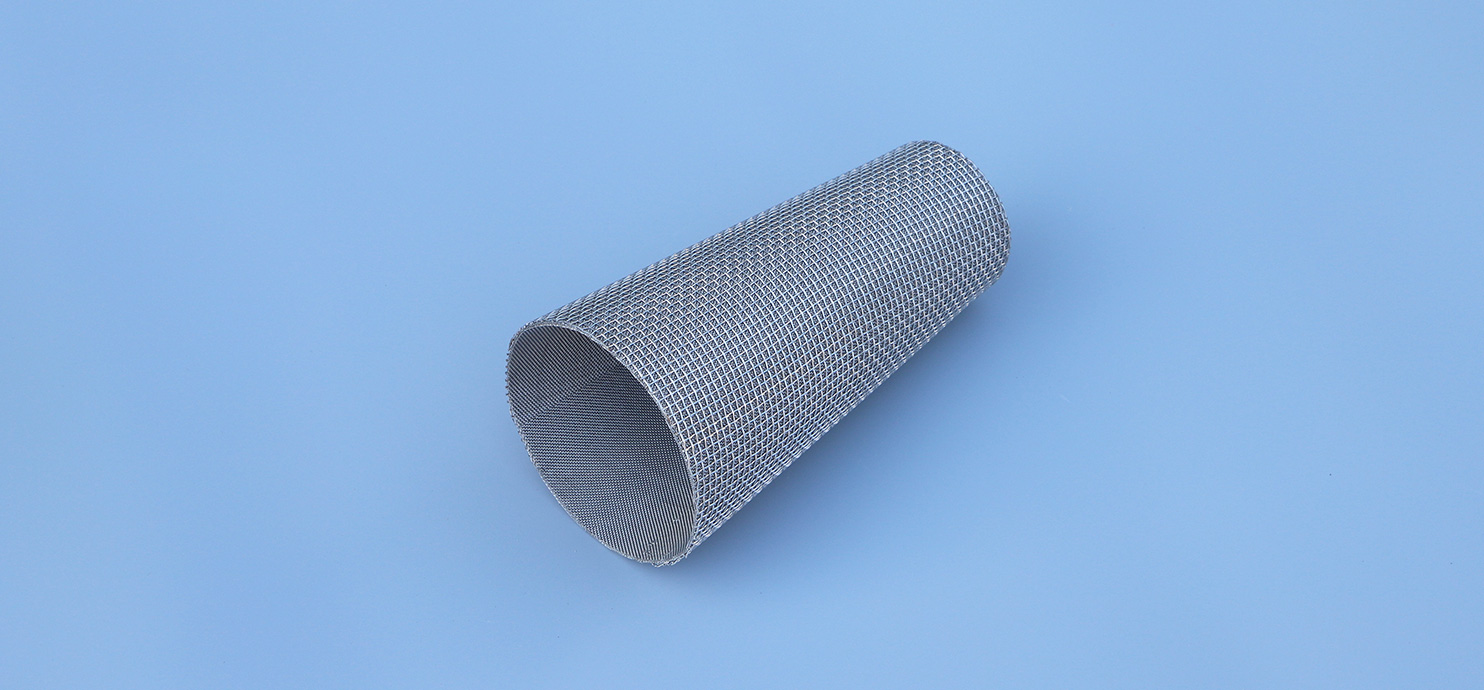

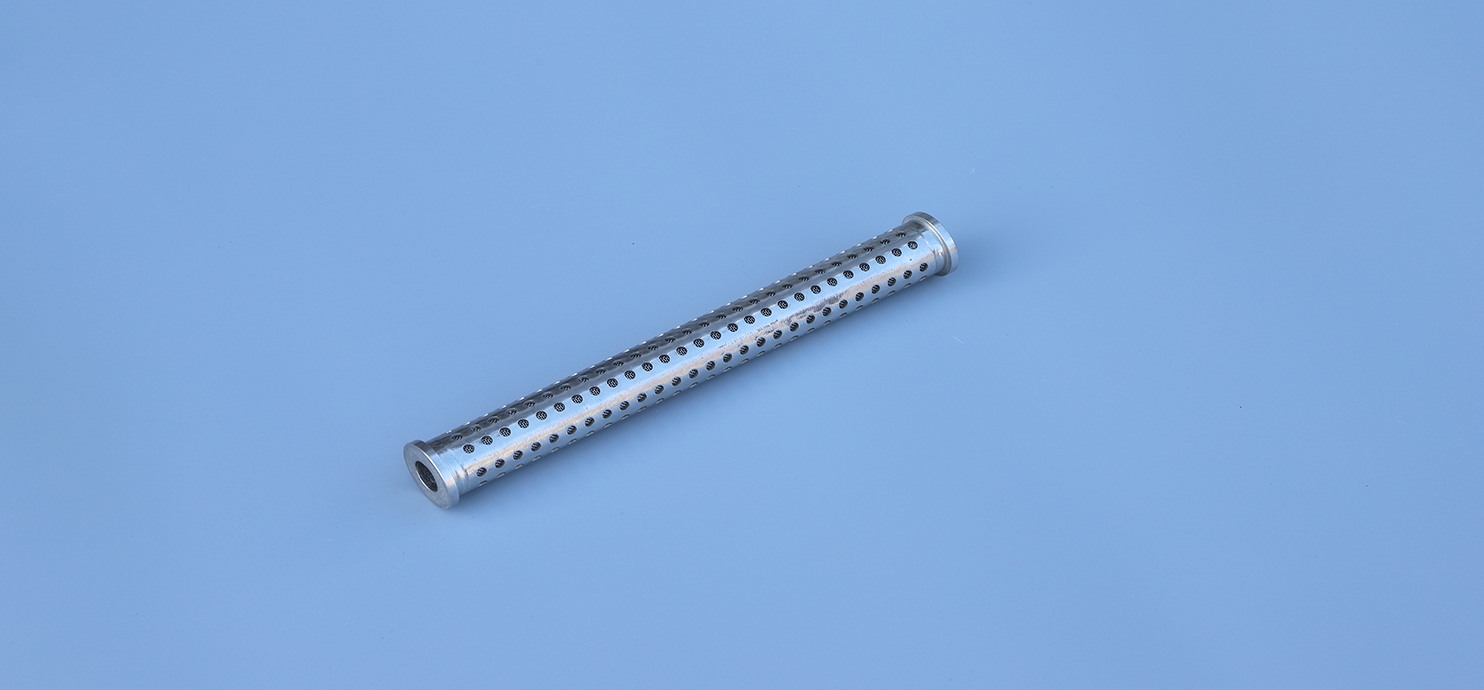

Metal Cylinder Filter Display

Metal Cylinder Filter Characteristics

Corrosion resistance: stainless steel cylinder filter with high-quality stainless steel as raw materials, can effectively resist chemical corrosion, extend the service life;

Acid and alkali resistance: the cylindrical mesh filter often uses woven metal mesh and sintered metal as the filter medium, which has excellent acid and alkali resistance and can ensure stable operation in strong acid and alkali environment;

Durable: cylinder filter pores uniform, reasonable structure, durable material, long-term stable use;

Easy to use: the cylinder design can reduce dead angles and ensure the filtration effect. Its surface finish is high, easy to clean, and can reduce the frequency of replacement.

Metal Cylinder Filter Specification

*Filtration rate: 3-500μm

*Temperature: up to 815℃

*Diameter: 14-800mm

Inner diameter: 27mm

Outer diameter: 67mm

Grommet

Inner diameter: 27mm

Outside diameter: 48 mm

*Micro rating: 2-840μm

*Flow rate: 10 gpm (38 LPM) per 10 inches

*Effective filter area: 1.7 ft²/ 10 inch length (1580 c㎡/254 mm)

*Length: 35-1500mm

Nominal length: 102mm, 248mm, 254mm, 495mm, 508mm, 745mm, 1016mm

*Material: stainless steel(1.4301, 1.4401, 1.4404, ALSL304, 304L, 316, 316L, 317L, 904L ), Monel alloy, Hastelloy alloy, etc.

*Filter medium: stainless steel wire cloth

*Construction: welded and crimped (no adhesives)

*Other diameters and lengths are available upon request

Metal Cylinder Filter Production Capacity

AHT/Hartong Wire Mesh Co., Ltd. is a set of design, research and development, production as one of the metal filter manufacturer, covers an area of about 40,000 square meters, the annual output value of up to 2l$ million, has been engaged in the field of metal filtration for more than 20 years, has a complete production line and dozens of professional metal filter engineers, support different specifications of cylindrical mesh filter customization. We will provide you with OEM services on a long-term basis to meet your specific filtration needs.

You can provide your application requirements and system parameters, and our professional engineers will give you a perfect solution.

Metal Cylinder Filter Certificates

AHT/Hartong Wire Mesh Co., Ltd. has a strict quality control system and has owned and fully implemented the following relevant certification systems:

ISO9001 Quality Management System Certification

ISO45001 Occupational Health And Safety Management System Certification

ISO14001 Environmental Management System Certification

ATF16949 Automotive Industry Quality Management System Certification

Authorized Economic Operator

Metal Cylinder Filter Packaging

Plastic film & Plywood case

Metal Cylinder Filter Applications

1. Petrochemical high-temperature gas filtration;

2. Purification of high-temperature flue gas in metallurgical industry;

3. Filtration and purification of various polymer melts in chemical fiber thin film industry;

4. Filtration and separation of various catalysts in the pharmaceutical industry;

5. Filtration of edible oil, beverages and various edible serums;

6. High-pressure backwash oil filter;

7. Filtration of other high-temperature gases and liquids.